Life Cycle Assessment

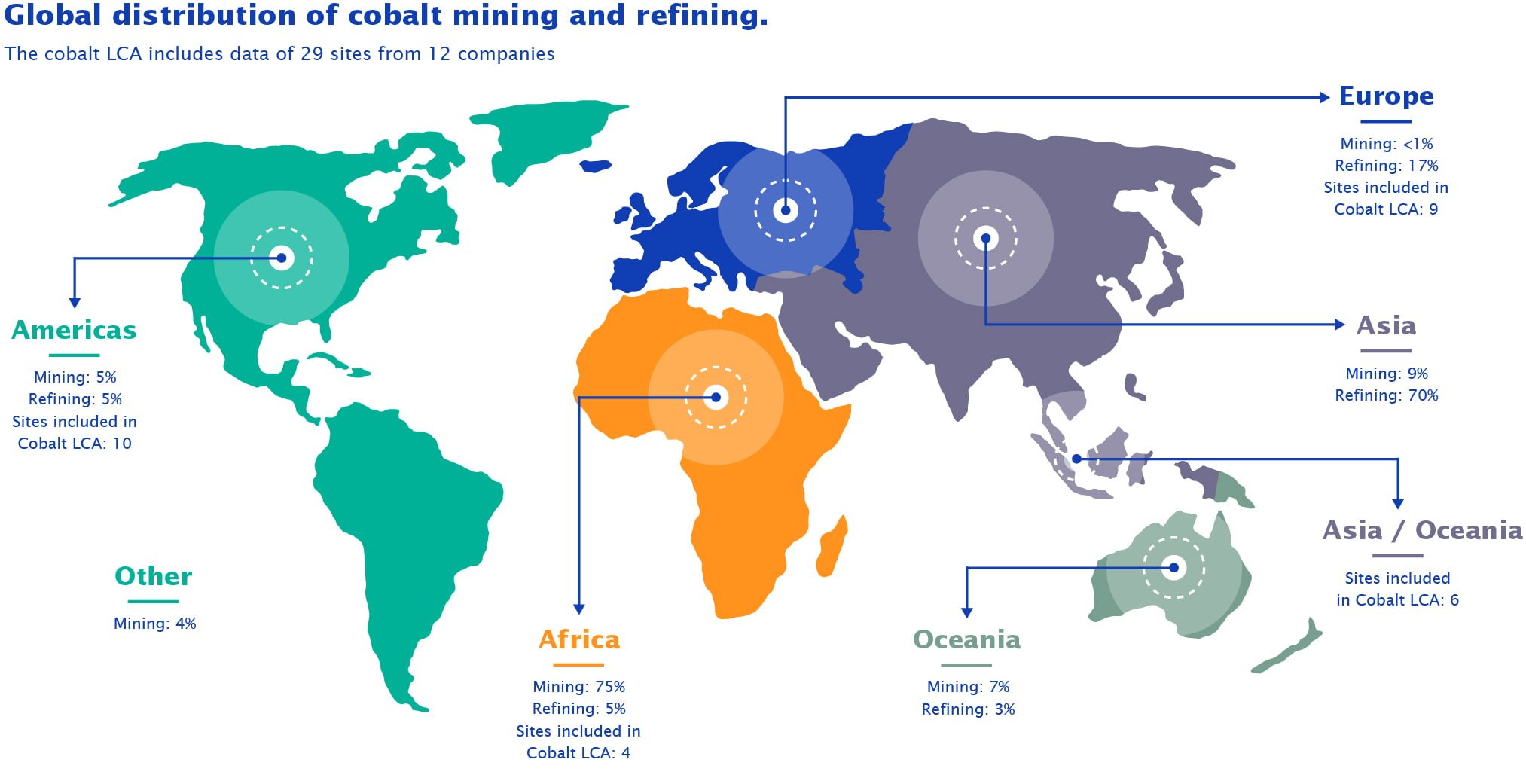

The Cobalt Institute conducted a Life Cycle Assessment of cobalt and cobalt compounds including cobalt sulphate to inform stakeholders about the potential environment impacts of the production of cobalt.

The study generated industry average cradle-to-gate datasets for refined cobalt metal (an update of the 2015 LCA), crude cobalt hydroxide, and tricobalt tetraoxide and cobalt sulphate heptahydrate – two cobalt compounds used primarily in battery applications – for the reference year 2019. The study followed the industry standard methodology set out in Harmonization of LCA Methodologies for Metals (2014) and was peer reviewed according to relevant ISO standards ISO 14040, ISO 14044, and ISO/TS 14071.

This study is a continuation of the 2015 Cobalt Life Cycle Assessment that focused on cobalt metal only and was the first of its kind in the cobalt sector.

Final results

| Impact category |

1 kg Cobalt Metal Co ~ 99.9% |

1 kg Crude Cobalt Hydroxide Co ~ 31.1% |

1 kg Tri-Cobalt-Tetraoxide Co ~ 73% |

1 kg Cobalt Sulphate Heptahydrate Co ~ 21% |

| Global Warming Potential [kg CO2 eq.] | 28,2 | 6,4 | 24,0 | 4,0 |

| Acidification Potential [kg SO2 eq.] | 0,44 | 0,13 | 0,34 | 0,29 |

| Eutrophication Potential [kg Phosphate eq.] |

0,01 | 0,0022 | 0,005 | 0,004 |

| Photochemical Ozone Creation Potential [kg NMVOC eq.] | 0,11 | 0,03 | 0,12 | 0,03 |

| Other environmental indicators | ||||

| Primary Energy Demand [MJ] | 561 | 179 | 356 | 101 |

| Blue water consumption [kg] | 992 | 863 | 1647 | 295 |

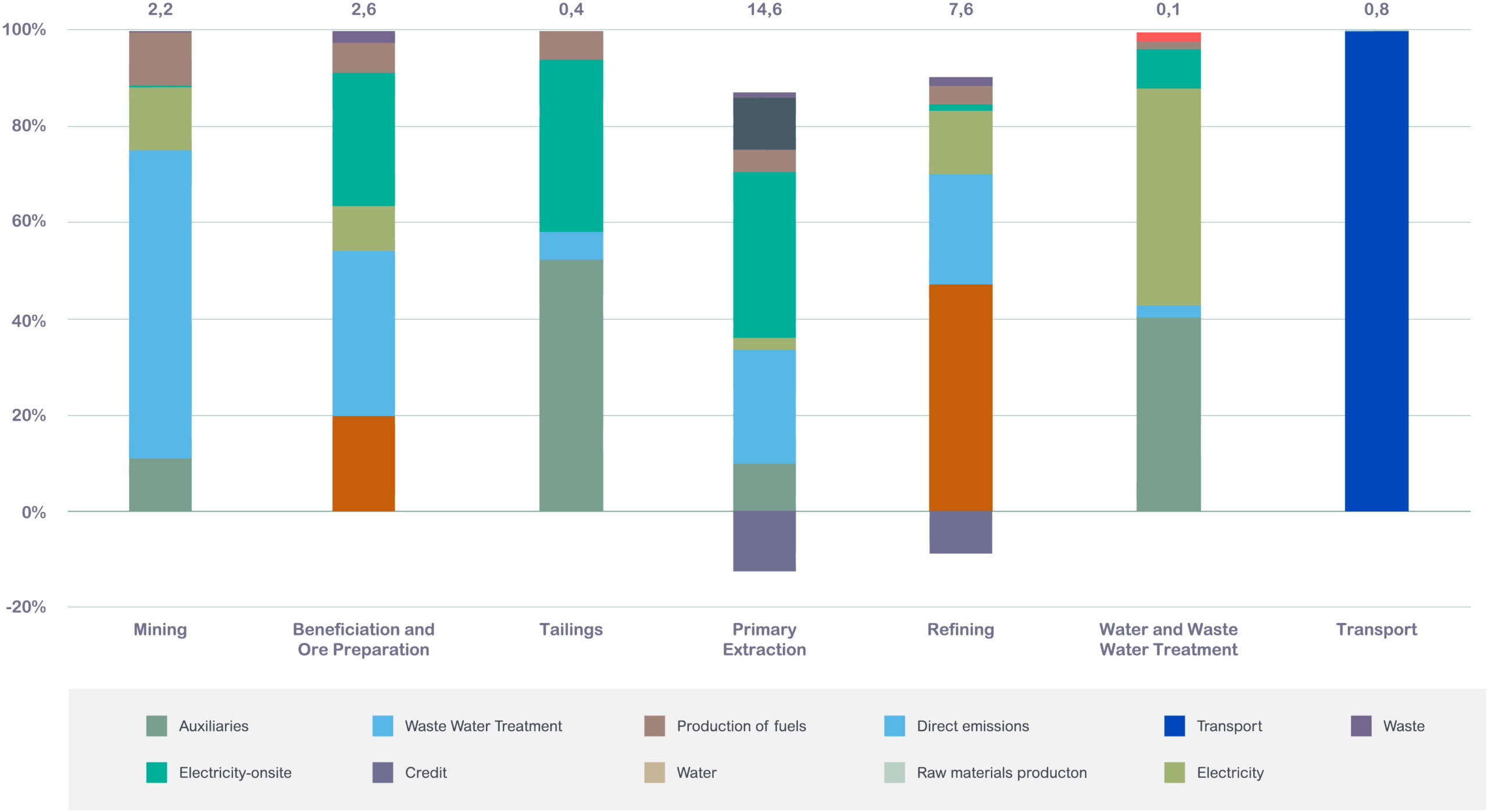

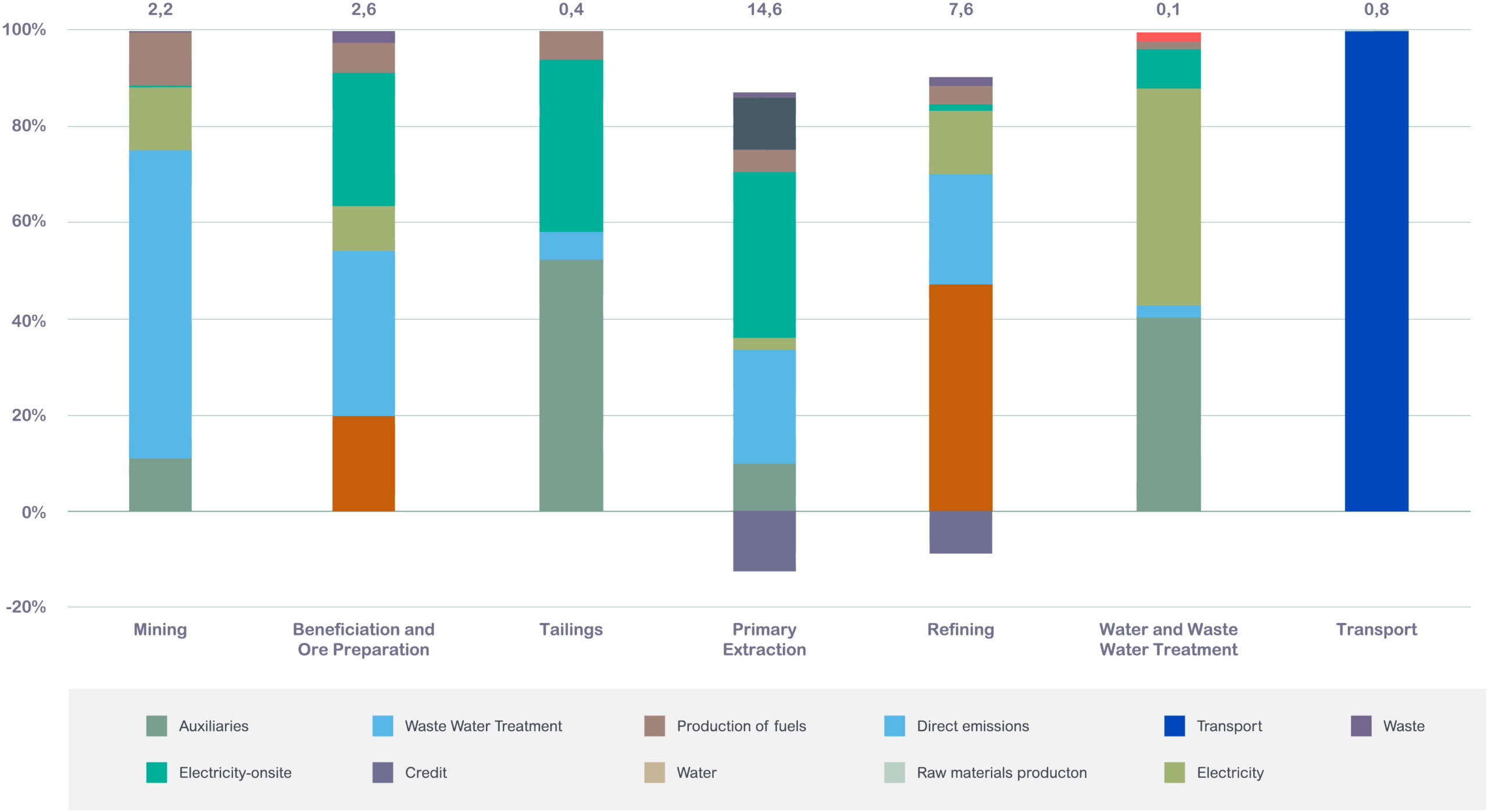

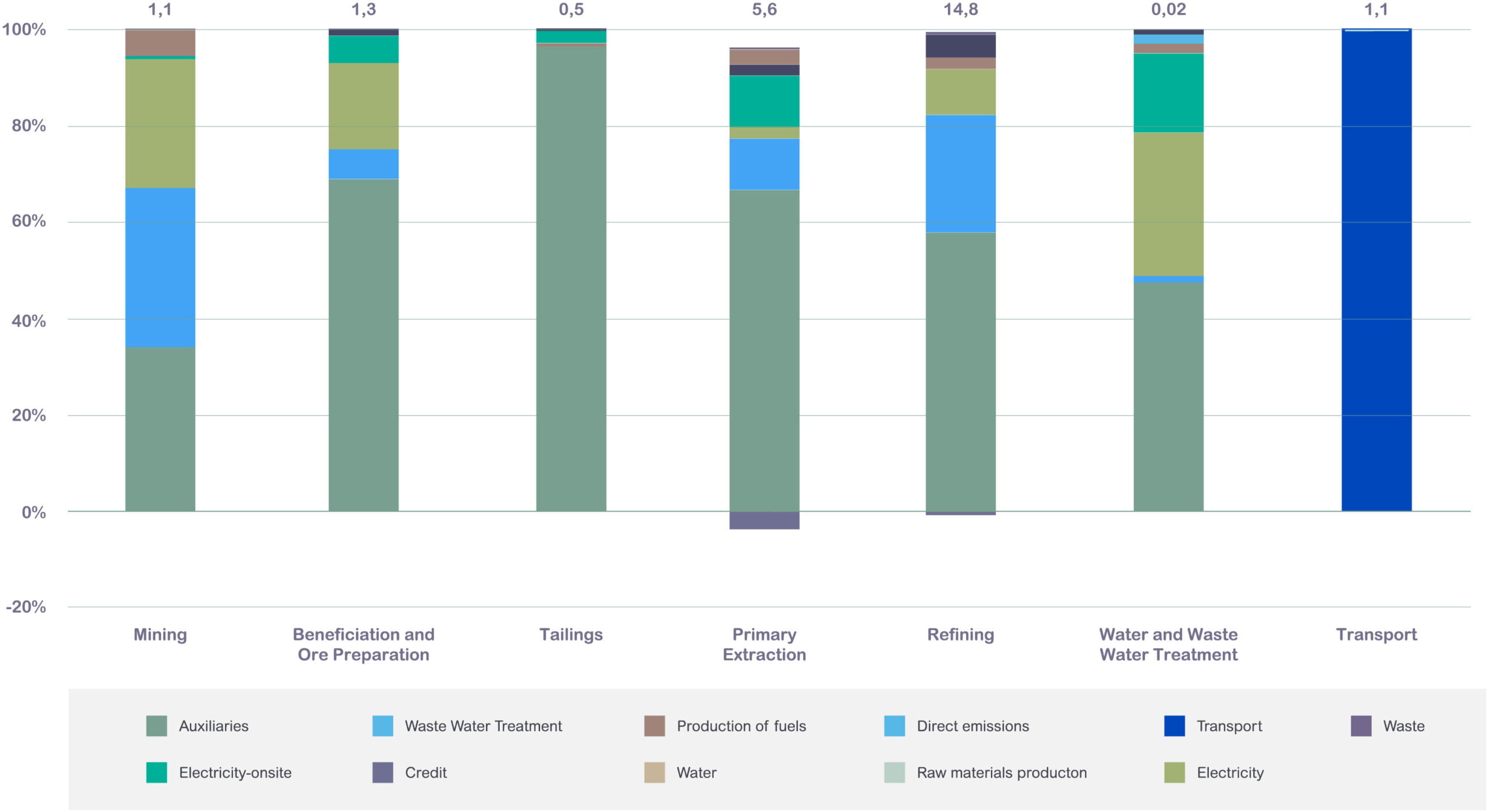

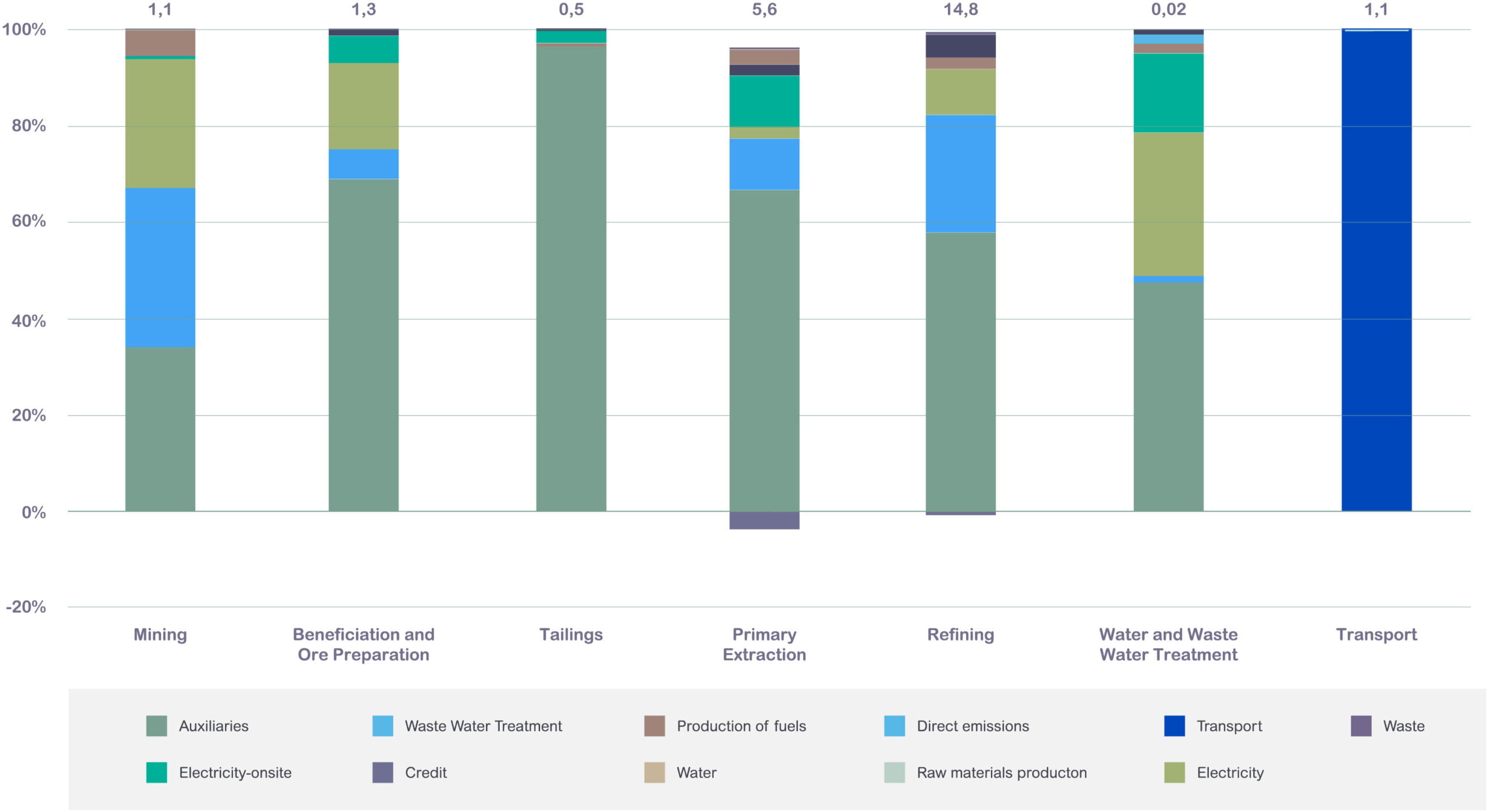

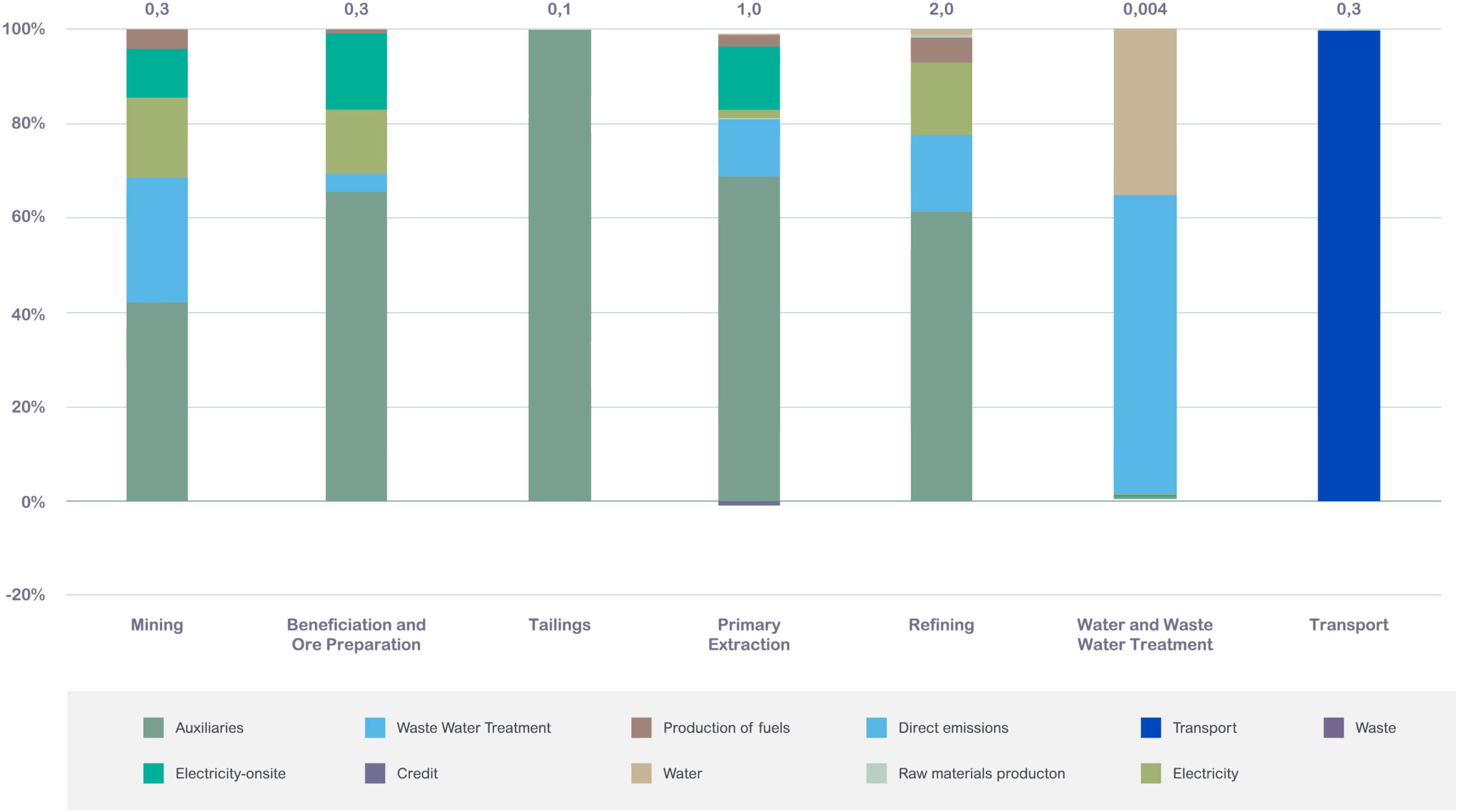

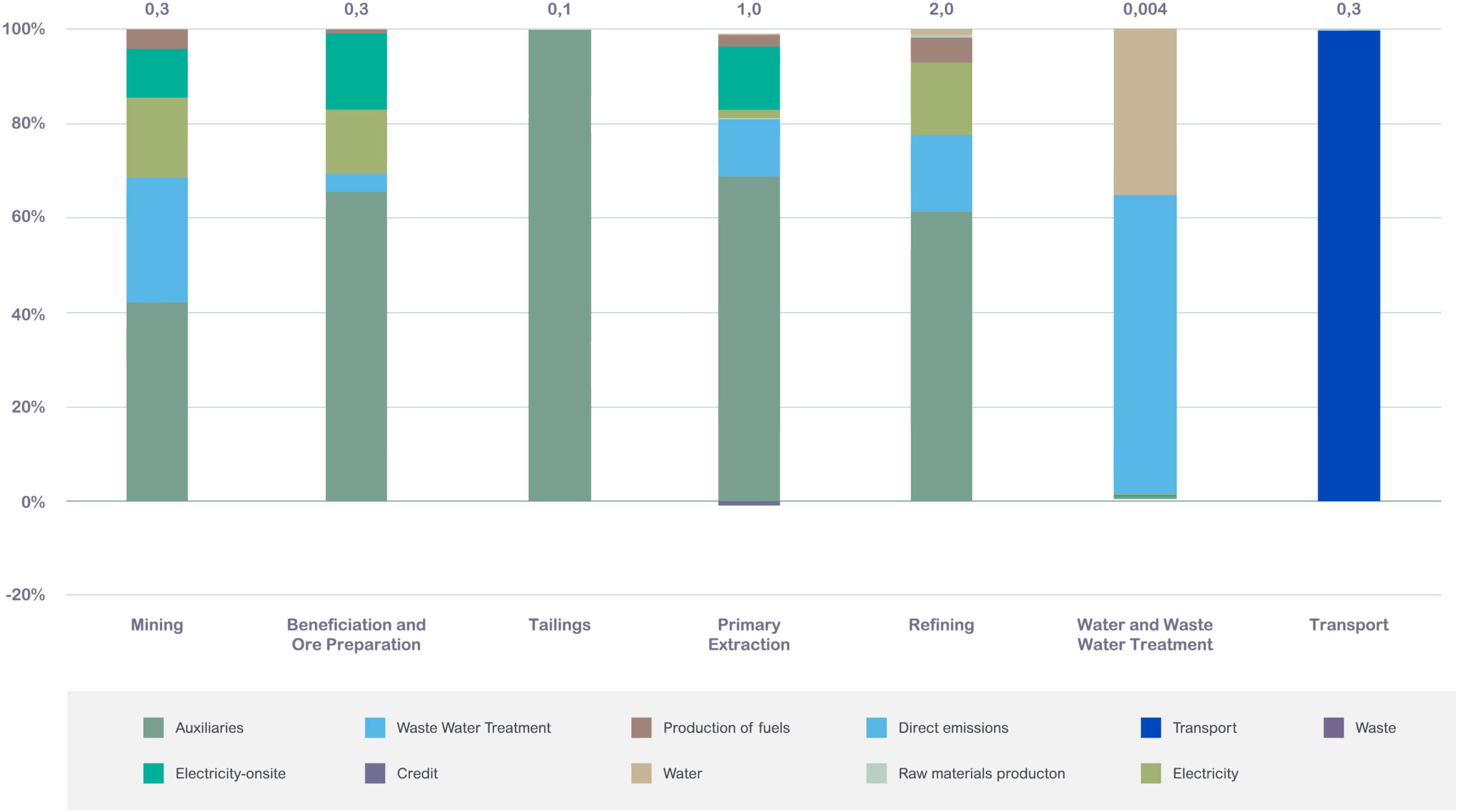

Greater disaggregation of these results provides valuable data that allows “hotspots” to be identified, where a particular process step of production might have a high impact. Electricity usage and direct emissions (e.g. diesel usage) are known impacts particularly for Global Warming Potential (GWP), however the report also identified Auxiliaries (i.e. chemicals) as a significant hotspot for GWP. It is notable that transportation, though a very visible impact in global value chains, accounts for between 2.8 and 4.6 percent of total product GWP.

These data will help industry decarbonise its value chains more effectively by directing attention first to those areas which are most carbon intensive.

Cobalt Metal

Contributors per process step for the GWP of 1 kg of Cobalt Metal.

Global Warming Potential (GWP 100 years) - Cobalt Metal [kg CO2 eq. / kg]

Global Warming Potential (GWP 100 years) - Cobalt Metal [kg CO2 eq. / kg]

Crude Cobalt Hydroxide

Contributors per process step for the GWP of 1 kg of Crude Cobalt Hydroxide.

Global Warming Potential (GWP 100 years) - Crude Cobalt Hydroxide [kg CO2 eq. / kg]

Global Warming Potential (GWP 100 years) - Crude Cobalt Hydroxide [kg CO2 eq. / kg]

Tricobalt Tetraoxide

Contributors per process step for the GWP of 1 kg of Tri-Cobalt Tetraoxide.

Global Warming Potential (GWP 100 years) - Tri-Cobalt Tetroxide [kg CO2 eq. / kg]

Global Warming Potential (GWP 100 years) - Tri-Cobalt Tetroxide [kg CO2 eq. / kg]

Cobalt Sulphate Heptahydrate

Contributors per process step for the GWP of 1 kg of Cobalt Sulphate Heptahydrate.

Global Warming Potential (GWP 100 years) - Cobalt Sulphate Heptahydrate [kg CO2 eq. / kg]

Global Warming Potential (GWP 100 years) - Cobalt Sulphate Heptahydrate [kg CO2 eq. / kg]

Key elements of scope

Cobalt Products Studied

Four key cobalt products were included in the study, building on the 2015 LCA which only looked at cobalt metal.

Four cobalt products were studied in the LCA. The functional unit for the study is per kg of product, with the products as specified below:

| Cobalt product | Cobalt content | Material form | CAS No. | Product uses |

| LME traded cobalt (refined Cobalt Metal) | ≥ 99.8% | Cobalt Metal: powder, cathode (broken or cut), ingots, briquettes, rounds | 7440-48-4 | A crucial alloying element in superalloys, magnets, tooling etc. |

| Crude Cobalt Hydroxide | 30 - 40% (31.1%) |

Unrefined cobalt compound Chemical formula: Co(OH)2 |

21041-93-0 | Intermediate product and precursor to other cobalt products |

| Cobalt oxide | 73% |

Cobalt compound; Tri-Cobalt Tetraoxide Chemical formula: Co3O4 |

1308-06-1 | The primary cathode component for Lithium Cobalt Oxide (LCO) batteries found in most portable consumer electronics |

| Cobalt sulphate | 21% |

Cobalt compound; Cobalt Sulphate Heptahydrate Chemical formula: CoSO4·7H2O |

10026-24-1 | A key cathode component in Nickel Manganese Cobalt (NMC) batteries used extensively in Electric Vehicles (EVs) |

Four cobalt products were studied in the LCA. The functional unit for the study is per kg of product, with the products as specified below:

| Cobalt product | Cobalt content | Material form | CAS No. | Product uses |

| LME traded cobalt (refined Cobalt Metal) | ≥ 99.8% | Cobalt Metal: powder, cathode (broken or cut), ingots, briquettes, rounds | 7440-48-4 | A crucial alloying element in superalloys, magnets, tooling etc. |

| Crude Cobalt Hydroxide | 30 - 40% (31.1%) |

Unrefined cobalt compound Chemical formula: Co(OH)2 |

21041-93-0 | Intermediate product and precursor to other cobalt products |

| Cobalt oxide | 73% |

Cobalt compound; Tri-Cobalt Tetraoxide Chemical formula: Co3O4 |

1308-06-1 | The primary cathode component for Lithium Cobalt Oxide (LCO) batteries found in most portable consumer electronics |

| Cobalt sulphate | 21% |

Cobalt compound; Cobalt Sulphate Heptahydrate Chemical formula: CoSO4·7H2O |

10026-24-1 | A key cathode component in Nickel Manganese Cobalt (NMC) batteries used extensively in Electric Vehicles (EVs) |

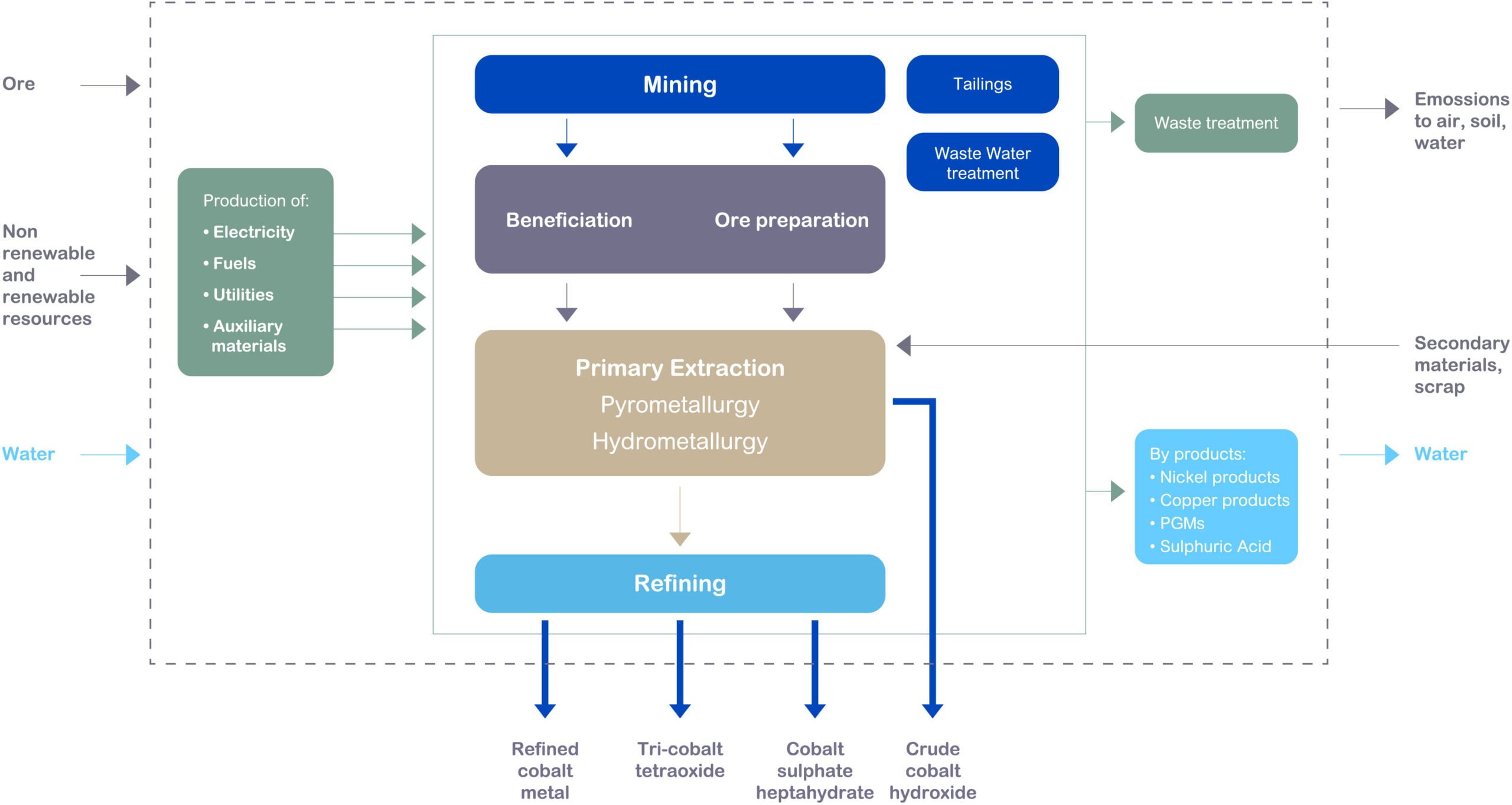

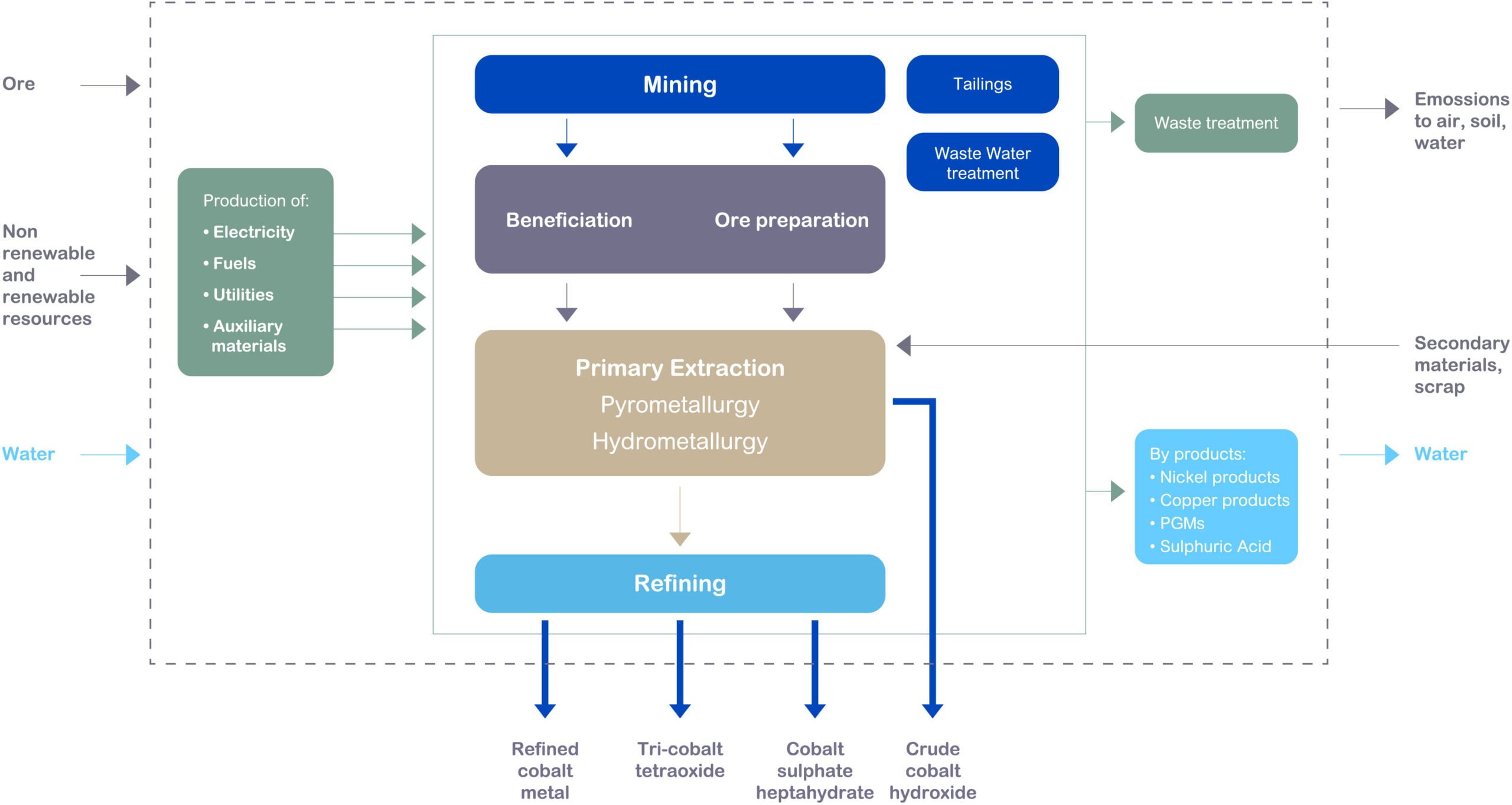

System Boundary

The cobalt LCA looks at impacts from cradle to gate (from mine to product refining).

System boundary

System boundary

Impact Categories

Four impact categories and two environmental indicators are reported in the LCA, using a functional unit of per kg product.

Impact Categories

| Impact Category | Unit | Description |

| Global Warming Potential (GWP100) | kg CO2 equivalent | A measure of greenhouse gas emissions, such as CO2 and methane. |

| Eutrophication Potential | kg PO43- equivalent |

Eutrophication covers all potential impacts of excessively high levels of macronutrients, the most important of which nitrogen (N) and phosphorus (P). |

| Acidification Potential | kg SO2 equivalent | A measure of emissions that cause acidifying effects to the environment. |

| Photochemical Ozone Creation Potential (POCP) | kg NMVOC equivalent | A measure of emissions of precursors that contribute to ground level smog formation (mainly ozone O3), produced by the reaction of VOC and carbon monoxide in the presence of nitrogen oxides under the influence of UV light. |

| Environmental Indicator | Unit | |

| Primary Energy Demand (PED) | MJ (lower heating value) |

A measure of the total amount of primary energy extracted from the earth. |

| Blue Water Consumption | kg |

Water consumption is water removed from, but not returned to the same drainage basin. |

Notably, USEtox is not used to assess human and ecotoxicity. There are significant shortcomings in its use for metals because the existing model does not consider complex metal properties such as essentiality of metals for life, background metals concentrations in the environment, metals environmental speciation and fate in the calculation of characterisation factors. This results in significantly lower in robustness than for the other impact categories noted above.

Impact Categories

| Impact Category | Unit | Description |

| Global Warming Potential (GWP100) | kg CO2 equivalent | A measure of greenhouse gas emissions, such as CO2 and methane. |

| Eutrophication Potential | kg PO43- equivalent |

Eutrophication covers all potential impacts of excessively high levels of macronutrients, the most important of which nitrogen (N) and phosphorus (P). |

| Acidification Potential | kg SO2 equivalent | A measure of emissions that cause acidifying effects to the environment. |

| Photochemical Ozone Creation Potential (POCP) | kg NMVOC equivalent | A measure of emissions of precursors that contribute to ground level smog formation (mainly ozone O3), produced by the reaction of VOC and carbon monoxide in the presence of nitrogen oxides under the influence of UV light. |

| Environmental Indicator | Unit | |

| Primary Energy Demand (PED) | MJ (lower heating value) |

A measure of the total amount of primary energy extracted from the earth. |

| Blue Water Consumption | kg |

Water consumption is water removed from, but not returned to the same drainage basin. |

Notably, USEtox is not used to assess human and ecotoxicity. There are significant shortcomings in its use for metals because the existing model does not consider complex metal properties such as essentiality of metals for life, background metals concentrations in the environment, metals environmental speciation and fate in the calculation of characterisation factors. This results in significantly lower in robustness than for the other impact categories noted above.

Representativeness

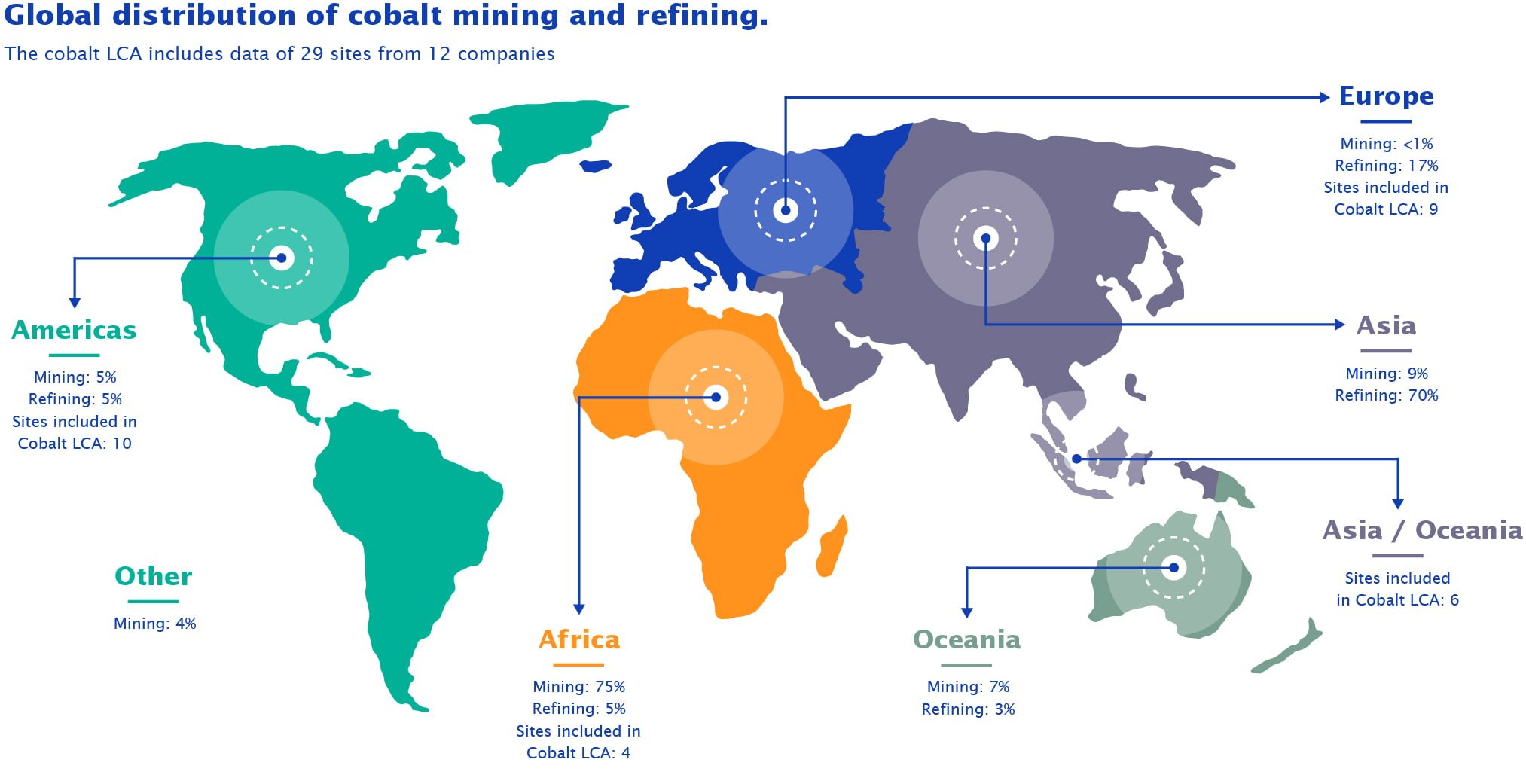

The LCA provides global average results for the cobalt industry, with an increased representativeness over the 2015 LCA.

The updated LCA has significantly improved representativeness over the 2012 reference year study, increasing from 30% to 55% for cobalt metal, and including three other cobalt products.

The geographical coverage of this study considers the global production of cobalt products (% on cobalt contained):

- 55% (26,818 tonnes) of globally produced refined Cobalt Metal. This is very high representativeness for cobalt metal.

- 37% (39,797 tonnes) of cobalt contained in global Crude Cobalt Hydroxide production

- 8% (4,439 tonnes) of cobalt contained in global Tri-Cobalt Tetraoxide production, and

- 9% (2,751 tonnes) of cobalt contained in global Cobalt Sulphate Heptahydrate production.

The relatively lower representativeness of Tri-Cobalt Tetraoxide and Cobalt Sulphate Heptahydrate reflect the fact that more than 70% of cobalt refining takes place in China, and no Chinese refiners were included in the study.

The updated LCA has significantly improved representativeness over the 2012 reference year study, increasing from 30% to 55% for cobalt metal, and including three other cobalt products.

The geographical coverage of this study considers the global production of cobalt products (% on cobalt contained):

- 55% (26,818 tonnes) of globally produced refined Cobalt Metal. This is very high representativeness for cobalt metal.

- 37% (39,797 tonnes) of cobalt contained in global Crude Cobalt Hydroxide production

- 8% (4,439 tonnes) of cobalt contained in global Tri-Cobalt Tetraoxide production, and

- 9% (2,751 tonnes) of cobalt contained in global Cobalt Sulphate Heptahydrate production.

The relatively lower representativeness of Tri-Cobalt Tetraoxide and Cobalt Sulphate Heptahydrate reflect the fact that more than 70% of cobalt refining takes place in China, and no Chinese refiners were included in the study.